Wyman's

Of Jasper Wyman & Son

Their wild blueberries sit in homes and commercial freezers around the world, and their famed recipes "light fireworks around your tastebuds." As one of the largest wild blueberry growers and frozen fruit suppliers in the world, Wyman’s spans multiple farm locations across the barrens of Maine in the U.S. and in New Brunswick and Prince Edward Island in the Canadian Maritimes. The vertically integrated company, originally founded by Jasper Wyman in 1874, has grown into an expansive operation requiring agile processes to support all aspects of the business. The team requires comprehensive operational and financial reporting capabilities, tools for traceability and sustainability, and a seamless mechanism for providing business processes from the field to the boardroom - and beyond.

The passionate people at Wyman's are the heart of the company. The team promotes the necessity of pollinators, coining the phrase No Bees, No Berries. To drive this home, they designed the Bee Wild Mobile to travel and promote pollination while serving up their own tasty frozen treats and education about the unique benefits of wild blueberries. The team also works to understand the effects of climate change on their crops, including launching the Wyman's Wild Blueberry Research & Innovation Center in cooperation with the Maine Agricultural and Forest Experiment Station at University of Maine.

The heart of this team at Wyman's includes the migrant workforce that returns each year for an intense harvest, and permeates through the yearlong staff dedicated to the individual farms. The core values of Wyman’s - do the right thing and seek a better way - underscore daily decisions, including those that led to Conservis.

At a glance

U.S. & Canada

Challenges

End-to-End Solution

Reporting for Stakeholders

Inventory & Activity Tracking

Bruce Hall, Agronomist for Jasper Wyman & Son, wanted to streamline operations and improve communication with team members. “B.C. - Before Conservis - we were an operation that was spread out across multiple time zones. We had many different farm management teams that operated in a silo. We had a tremendous amount of spreadsheets or hand-written note tabulation that no one really had access to.”

It did not take long to find the solution within Conservis. “We needed a planning tool. How can we communicate easily across our team and how can we capture true costs going into the fields? We had ways of doing that in the past before Conservis, but it was incredibly challenging to ever obtain. It would take us about two to three months' worth of processing information to get it. Now, we're doing it with a few clicks of a mouse.”

Results

Easy Access to Financial Reporting for Stakeholders

“We had a board of directors that wanted to know how we were performing and [prior to Conservis] it took us so long to provide them with the information on an annual basis, longer than they really wanted us to take, but that's how complex our operation was.” As one of the largest wild blueberry growers and frozen fruit suppliers in the world, it is no wonder that Bruce Hall, Agronomist at Jasper Wyman & Son, faced challenges gathering timely, comprehensive reports for stakeholders.

“At the end of the day, we're farmers. We're not accountants. We're not financial planners, so we need to have those tools in hand easily so we can do what we do best.” Bruce searched for a system to ease the frustrations and deliver corporate reporting required of any large-scale producer, and he quickly found Conservis. “What I really think sets Conservis apart on the financial reporting side of things is the ability to set specific field plans and understand the budgets going on at the field scale of your operation.”

Bruce says Conservis makes it easy for the team at Wyman's to run through operational activity and financial scenarios in tandem. "If we choose to do this activity, then it will cost us X. If we choose to do that activity, it will cost us Y. We can then assess what the return on those activities will be and we can make a choice together."

The Wyman’s team uses Conservis data to drill down at the field level to easily create and analyze economic plans and assessments. Bruce appreciates that he can share Conservis reports with senior management as key performance indicators of their farm activities. “Not every location is as productive as another, so being able to dive in and have that level of financial control and assistance to decision making is quite valuable.”

"In the end, it's the budgeting that really matters to me because I have to answer to the CFO in regards to how much money we're spending on the farm.”

Better Decisions with In-the-Moment Work Orders & Inventory Management

Conservis work orders and tickets have improved labor management at Wyman’s, says Greg Jobe, Operations Manager for Wyman’s Prince Edward Island (PEI) division. “It's very simple. Once they [field workers] understand the field they're in, they understand the chemical and the spray recipe from the work order.” Workers bring up the orders on their mobile phones or tablets, including the rates to be applied.

Bruce Hall, Agronomist, appreciates the value of work orders among Wyman’s employees. “They see that because we have this [Conservis], the farm managers now have the in-the-moment understanding of where work orders or activity tickets are and what our operations look like. In the grand scheme of things, they can make better decisions.”

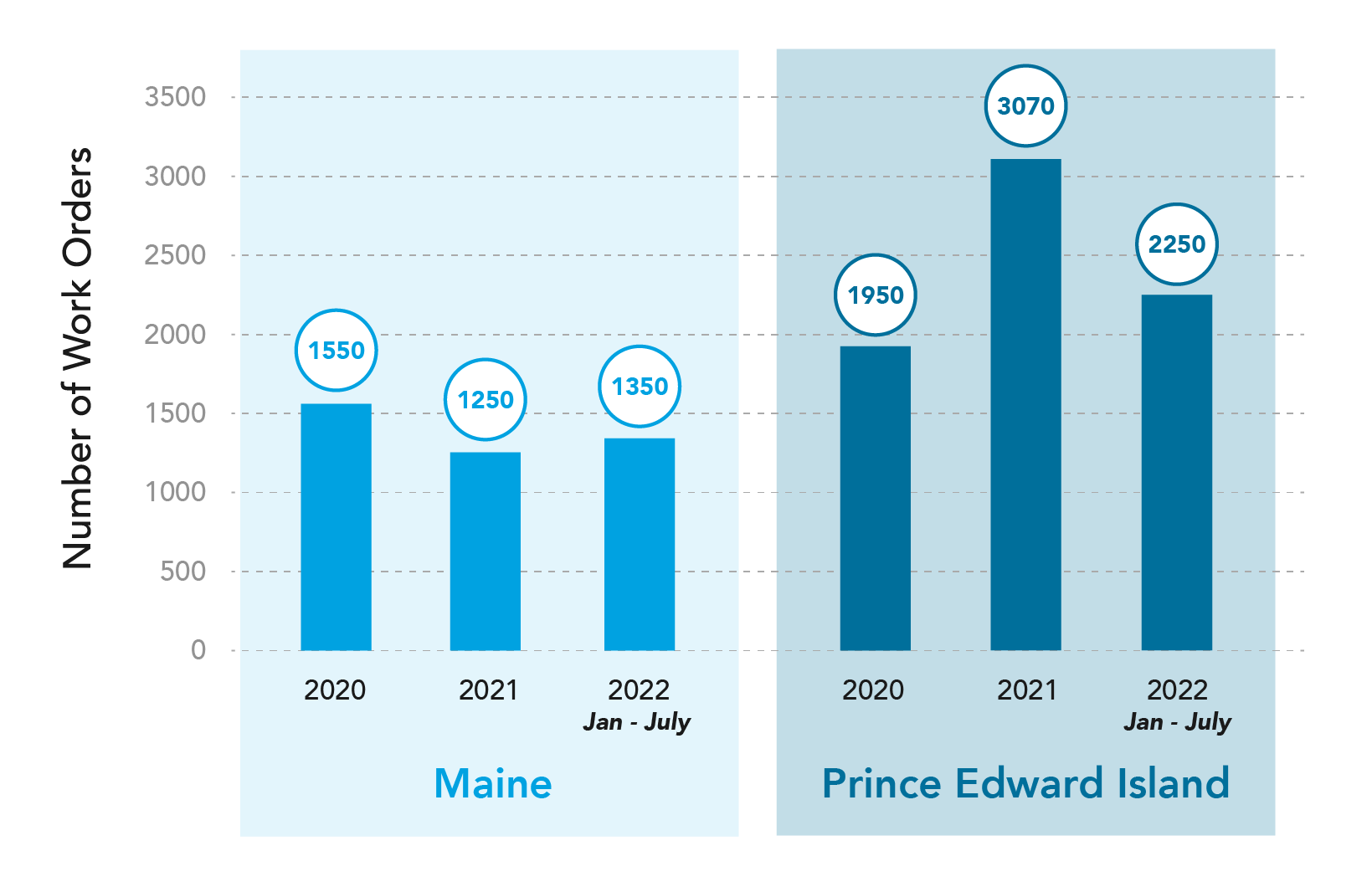

Multi-Activity Tracking

The work orders at Wyman’s go far beyond spraying fields, generating thousands of tickets for a wide range of processes. Greg uses work orders for activities such as “land and road maintenance, mowing operations, and putting the bumblebees and honeybees out for pollination.”

About half of the tickets created are billing-related at Wyman’s and Greg sees strong value in the accuracy provided with Conservis data. “Being able to produce those tickets for administration so they can bill properly without debate, is my favorite thing about Conservis.”

Inventory Management Begins with Work Orders

The vast production at Wyman's relies on work orders as just one piece of the puzzle. The work orders translate into activity tickets that directly correspond to any related inventory update. Greg appreciates this seamless connectivity. “Conservis' really strong point is its inventory management. It's easy to find out what you have in place. When tickets are complete and chemicals are left over, they can come back and be put into inventory. It's easy to see where the chemicals are and when they've been used.”

“Conservis’ inventory management is exceptional. We are running the lowest inventory levels at Wyman’s today.”

Agile, End-to-End Farm Management Solution

Bruce Hall, Agronomist, knew early on that Conservis made the short list. “Once we began investigating available platforms, Conservis stood head and shoulders above the rest. What really set that apart were the people who come to the table, the attention to detail, the wanting to figure out solutions, learn about your business' challenges, and provide the solutions to those challenges.”

Kevin Byers, Senior Farm Manager for Jasper Wyman and Sons Canada, Inc., agrees. “We looked at a number of different software programs, but we couldn't find any people that were willing to listen and had the ability to make changes on the go, and to really sit down and discuss what our needs were.”

Bruce didn’t always have this agility at his fingertips. “You lay out your farm plans in the winter, spring comes, weather happens, delays happen, and modifications need to happen. Through Conservis, we not only can easily make that baseline plan for the farm season, but it allows us to edit our plans. We can make those changes on the fly.”

“Conservis was the end-to-end solution. Our accounting department pulls data from Conservis that then goes into their ERP at the corporate level of the company, and then that's shared with Wipfli [Wyman's accounting firm]."

Bruce and Kevin had been searching for “an all-inclusive management software program that could bring everything together in one place.” Kevin looked at a number of different software programs, but found that only Conservis delivered end-to-end. “Some of the other programs that we looked at didn't offer all the agility of Conservis. As an overall package, Conservis held it all.” They rely on the data of Conservis to bring the company together, and he says they are able to view the entire farm operation, and in turn the end goals of the company.

Kevin buys into the success he sees with Conservis. “We’re a unique business, the wild blueberry business. We needed something that was very unique, and Conservis provided that for us.”

Reliable, Real-Time Spray Management

“My favorite thing about Conservis is the management of spray records.” Greg Jobe, Operations Manager, relies on Conservis spray records for “an exact record of when that chemical is applied, who applied it, and the conditions, and it's captured in the same way each time.”

For Greg, spray management begins with determining how many chemicals the farm needs on a field-by-field basis. With Conservis, Greg says that it’s “simple to ask the system how much of a particular chemical I need to order.”

“You have confidence that the amount of chemicals you wanted to put down are right, and so is the quality of the documentation. Conservis removes all hesitation.”

Each spray throughout the year at Wyman’s has to be managed, curated, and finalized, and with 10 sprays across 70 fields, that is easily 700 tickets. “In real-time I can find out when those activities have been done,” says Greg. This is essential for the agronomy side of the business where the team at Wyman’s needs to have immediate access to spray reports, including weather conditions. “There's a legal aspect where we have to meet the label rates. We can go back and see what the conditions were at any time.”

“Before Conservis management of our spray records, you could always file paper, but it's all states of disarray and calculations are incorrect. Conservis records are always accurate and easily accessible.” Greg says this accounts for quality improvements seen across the operation. “You have confidence that the amount of chemicals you wanted to put down are right, and so is the quality of the documentation. Conservis removes all hesitation.”

Wyman’s also utilizes the spray records when timing their harvest, says Bruce Hall, Agronomist. “If there's pre-harvest intervals [PHIs, the minimum time between last application of a pesticide and when a grower can harvest] that have to be in play at a certain field, then you can know really quickly this is when that field was sprayed and we then can back off X number of days to begin harvest.”

Confidence in Real-Time Plans vs. Actuals

In his role as Agronomist with Wyman’s, Bruce Hall is heavily involved in the farm planning process, including financial projections. “The actuals versus the plans is really where I'm at. It's very easy and transparent for me with Conservis to provide our finance office with what my cost centers need to look like for next year.”

“The future of farming is automation. It's digitization.” Bruce uses Conservis digital data to understand an acre-by-acre assessment of plans vs. actuals. “I know I'm farming X number of acres. I can very easily give projections on what the cost is going to be. I can show revenue by inputting predicted yields through the model.”

“We were able to finally for the first time truly analyze our financials at the company, as opposed to providing maybe very high-level assessments. We're now providing actuals very easily.”

Greg Jobe, Operations Manager at Prince Edward Island, says Conservis covers what he needs to get the work done. “It provides my main three functions of planning, monitoring and verification. Plan, monitor, verify. Conservis hits all three of those for me.”

He credits Conservis with significantly more accurate and accessible data, where before their unreliable data led them to consistently overestimate expenses out of extra caution. “Now we're able to really hone in and we have the confidence to project almost to the dollar what we're going to be spending next year.”

These more accurate projections allow them to “show how profitable our farm operation is throughout the whole company. At the farm level of the company, we can show our farm expenses, the field price for blueberries, and our total growth in the Conservis system.”

Traceability & Food Safety Audit Documentation

April Norton, Senior Director of Human Resources at Wyman's, relies on Conservis to monitor the connections between people and produce. “We're managing every bit of fruit that comes off the field. We need to know who grew it, where it came from, when it was harvested, where it came into, where it's going. The traceability is huge for us.”

Kevin Byers, Senior Farm Manager, agrees. “I believe that traceability is a very important factor in all aspects of operations and in consumer consumption. Conservis offers the ability to search back by date, time, year, application, and pesticide.”

He likes that Conservis provides the broad and reliable picture of traceability, and he has full confidence in the data. “The beauty of it is that it's not a handwritten document. It's printed and it's on the computer and it can't be adulterated.”

If audits happen, the Wyman’s team is prepared. Kevin recently used Conservis data to qualify in Canada for their Safe Quality Food (SQF) program. “We passed the audit with flying colors.” Kevin reiterates the value of Conservis data in relation to audits. “For us as a company in the food business, we're dealing from fresh to frozen to consumer. If we do ever have a recall, we have the documentation to rely on quickly.”

Audits are integral to the food industry. Bruce Hall, Agronomist, values the data and reports of Conservis for this reason. “I can be on vacation, on an island somewhere in the world, and can hand that information to our QA team with a couple clicks of a mouse button.”

“We've had several audits since Conservis, and every one of those auditors have been thoroughly impressed by the level of detail and insights that Conservis brings to the food safety auditing process.”

Clear Cost of Production & Capital Ask Support

Kevin Byers, Farm Manager, says “one of the beauties of Conservis” is having everything available in one place, no longer siloed. “We no longer need to go through a paper trail to try to come up with the cost of production, which oftentimes used to be just a guess because we didn’t have the time to go through all that.”

“We can get down to a cost per pound, but we can also look at it as a cost per field, and we can look at it as a cost per acre.” Kevin relies on these various ways to calculate cost of production to make informed decisions.

Conservis brings more accurate cost measurements and allows the Wyman’s team to react to wholesale and field price changes, thus reducing costs. As the manager of three farms, Kevin needs information fast. “I need to be able to go onto the computer or my phone and get real-time data so I can make decisions on the fly. I'll look at Conservis, we make a decision, and we can make it happen instantaneously.”

Bruce Hall, Agronomist, also relies on Conservis information. “It provides the cost of production quite easily by tracking our expenses from the operator level. We put in our revenues from our harvest side, and it provides us that automatically.”

“Conservis allows us to track all of our consumables easily, plus the equipment component whether you lease or purchase your equipment.”

On their Prince Edward Island farms, they have even been using Conservis to track the costs associated with bringing bees to the fields. “I was able to use that information to make sense of buying into a bee operation to return more dollars to us as a corporation.”

Cost of production knowledge drives financial decision making. “I've used a lot of what's in Conservis to formulate my capital asks,” says Kevin. “We're able to pull a lot of that documentation together.”

Flexible Onboarding & Responsive

Customer Service

In March of 2020 Wyman’s was planning its onboarding process with Conservis. “We had all the training materials planned, the itinerary planned out, plane tickets purchased,” says Agronomist Bruce Hall. That was before COVID closed much of the world.

The challenges of a global pandemic did not stop the onboarding process from moving forward, especially with the Conservis Customer Support Team leading the way. “Under incredibly strenuous situations, we were able to utilize other packages and technology to provide those training services in lieu of being in person,” recalls Bruce.

“It [the onboarding process] was incredibly flexible and I was very, very happy with how Conservis worked with Wyman's to pivot in that situation under unprecedented challenges. And it was successful. It was very successful. We had very good acceptance right out of the gates across all of our team members,” says Bruce.

Wyman’s believes strongly in transparent teamwork, and Bruce wanted to make sure the platform they chose would be accessible and agile for all of them. “Most importantly, it's the people with the tablets in their hands, the people in the tractors doing the work. You have to have them on board with what we're doing, and they were right out of the gates.”

“The willingness of Conservis customer service and engineering teams to think about new solutions that may be not even offered at Conservis today in partnership with our business as well - that's something.”

Engaged Employees Relieve Labor Shortage

“If you're asking people to input data and you never share with them the output, they're not really going to see the value in what they're doing and why they're doing it.” For this reason, Bruce Hall, Agronomist, says they make it a point to share Conservis data with their workers.

“Through using Conservis, we've been able to optimize our spray operations, for example, and they see that.” The real-time understanding Wyman’s farm managers have of the data they enter gives them a big picture view, empowering better decision making. “Those better decisions are streamlining the work the employees do and they buy in.”

"Farming is hard. It's hard to promote and to move people in farming. But if we're offering them more opportunities to learn and grow, and they're taking them, then they're becoming a better person. They're more driven. They're a more engaged employee for us. Conservis has helped us, definitely, that way."

April Norton, Senior Director of Human Resources at Wyman's, says, “It's my job, my team's job, to always be looking for better ways to assist our people, offer them the tools to do their job better, more efficiently, more accurately. That is happening with Conservis.”

When April first joined Wyman’s, she soon learned the local workforce was only able to supply approximately 20% of what the company needed. “We really started shifting gears early on to make sure that our migrant workforce was as strong as it could be.” The Wyman’s migrant workforce now runs up to five generations deep. “This is grandparents, great grandparents, and now themselves… their children are coming.”

“With Conservis we're putting the power in the hands of the people who do the work. There's value in that, in making people aware of what they're doing, and also arming them with the tools to have greater ownership over the process."

In addition to a low local employment pool, April recognizes the traditionally high turnover rate in manufacturing jobs. “We're up over 40% nationwide. Wyman's has been able to sustain those numbers at around the 10 to 15% range, which is astronomically lower compared to our competitors.”

Wyman’s leans in to the Conservis platform to help with their labor management, and sometimes that means appreciating fewer headaches for everyone involved. “Instead of having to call Kenny at seven o'clock at night to say, ‘Did you get down there to that neck of the woods and spray his field?’ I can call Jerry and say, ‘You can go in tomorrow. Your field was done two days ago.’ That's massive, not having to call your folks up and say, ‘What'd you do?’“ With Conservis tickets on the tablet Greg Jobe, Operations Manager, has answers at his fingertips, saving himself and his crew time and energy.

Conservis benefits extend beyond data management to employee growth and retention. “It's making their jobs a lot easier. The information is coming through a lot more accurately, and the accessibility to that information is so much easier. It’s a huge benefit to the people, allowing them to continue to grow and move within their roles,” says April.

Aligned Culture & Dedication to People

“My favorite part at Wyman's is I have the ability to enhance the lives of people directly, and I get to see that play out every single day,” says April Norton, Sr. Director of Human Resources. “You are family here every day. We spend the majority of our time together, Monday through Friday, and it is the most enjoyable time. And that really keeps people wanting to come to work every day.”

Bruce Hall, Agronomist, echos this. “At Wyman's, we have two core values and they are: do the right thing and seek a better way. And we instill that culturally across everyone at our organization, whether that's on farm or in manufacturing facilities and beyond.”

It was in seeking a better way that Bruce found Conservis. The two companies share similar values and driving missions, and Bruce uses the platform to support the company culture. “If you cultivate a sense of pride at your workplace, then you can share with people the output that's coming out of Conservis. They're going to see the value in what they're doing and why they're doing it.”

Wyman’s carries this mantra of putting people first across all levels of the corporation. “Being aligned with a strong value-oriented company has been extremely important to consumers, and we are checking all of the boxes. We are going far above and beyond what other companies are recognizing of what the consumer wants,” says April. “This isn't just about putting fruit in someone's mouth. This is about standing for something that we're proud of and people want to be a part of.”

”The complete differentiating factor of Conservis is the people. Catering specific solutions to how this farm operates differently from another farm, that level of attention to detail is unmatched in the marketplace.”

No matter where you explore at Wyman’s the culture permeates across departments and activities. Manufacturing Manager Adam West, a 4th generation employee who has been with Wyman’s for 22 harvests, says with a grin that even though harvest time can be the most challenging, “It is like my Christmas.”

This sense of pride in the company aligns with the decisions they make. Wyman’s provides Blueberry School for young children during harvest while their parents work. The company ensures their migrant workers have access to health and dental care. Each decision Wyman’s makes is with people at the heart of it. This extended to when they chose their farm management system.

"We knew that we needed service to be there for our people when needed," says Bruce. As he and Kevin Byers, Farm Manager, searched for the right platform, they wanted their people, and their production, to have full support. Kevin says they found this with Conservis, and the future is strong. "In the future, as we develop together and work together, we can build a better product for both of us."

Bruce echoes this. “We get better together. Even if you sign on today, this is what you're getting but three years down the road, both of us have gotten more than we ever signed on to.”

Is Conservis right for you?